The filtered water enters the body from the inlet, and impurities in the water accumulate on the stainless steel filter, creating a pressure difference.The differential pressure switch is used to monitor the differential pressure change at the inlet and outlet. When the differential pressure reaches the set value, the electric monitor gives the hydraulic control valve and drives the motor signal.

After the installation of equipment, technical personnel debugging, set time filtering and cleaning conversion time, treated water inlet into the body, normal operation of the filter, accumulator manufacturer after reaching set cleaning time, electric monitor signal of hydraulic control valve drive motor, drive motor, the rotating brush, cleaning filters, at the same time open the drain valve.The whole cleaning process only lasts for tens of seconds. At the end of the cleaning, the control valve is closed, the motor stops rotating, the system returns to its initial state and starts the next filtration process.

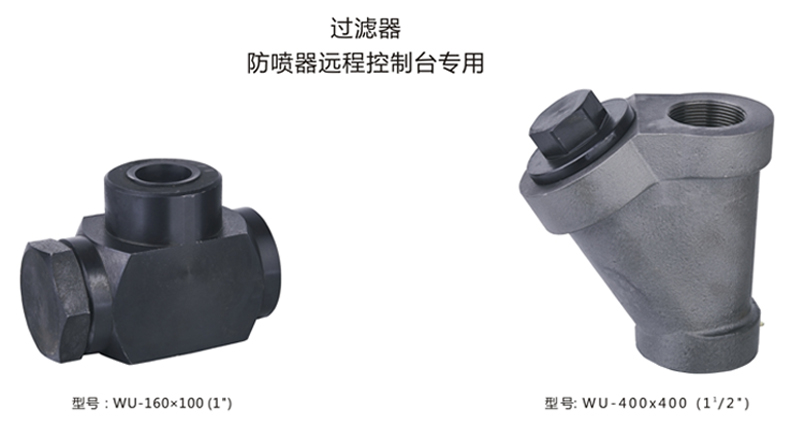

The shell of the filter is mainly composed of coarse filter, fine filter, suction pipe, stainless steel brush or stainless steel, sealing ring, anticorrosive coating, rotating shaft, etc.